Innovative special-purpose machines for sustainable recycling solutions

Welcome to our company specialising in custom machinery for recycling technology. We develop and manufacture high-quality cable granulation systems, dismantling systems for used car catalytic converters, and other products for the processing of non-ferrous metals. Our recycling technology is made in Germany and offers bespoke solutions for all requirements.

Quality

Products

Discover our wide range of machines and systems.

CONTACT

We are here for you!

Contact us today to learn more about our services. Our dedicated team is available to answer your questions and assist you in selecting the best solutions for your needs. You can reach us by email, phone, or through our online contact form.

PLANNING

Your vision, our expertise!

We offer comprehensive project planning and design services. Our team of engineers works closely with you to bring your ideas to life. We utilise the latest technologies and software to ensure that your products meet the highest quality standards.

MANUFACTURING

Quality that lasts!

Our manufacturing process enables us to produce a wide range of products with precision and efficiency. After production, we ensure thorough quality control and smooth commissioning. Our goal is to deliver products that not only meet but exceed your expectations.

Efficient

Customised solutions for all requirements

Our custom machinery solutions offer a wide range of processing systems, from small to large scale. We design and manufacture cable granulation systems, dismantling systems for processing used car catalytic converters, and other products for the treatment of non-ferrous metals. Our recycling technology is “Made in Germany,” and we provide tailored solutions to meet every need.

FAQ

Find answers to frequently asked questions about our products and services here.

How does a cable granulation system work?

Cable granulation systems are specialised machines used in the recycling industry to dismantle cables and recover valuable metals such as copper and aluminium. They are an essential part of modern waste management, helping to minimise the environmental impact of electronic waste.

There are two main types of cable granulation systems: wet and dry separation systems.

Wet separation systems (W-SERIES): use water to separate the insulation from the metal cores of the cables. This process is particularly effective for separating fine wires, which can be difficult to process in dry separation systems. However, wet separation requires effective water treatment to ensure no harmful substances are released into the environment.

Dry separation systems (D-SERIES): use airflow and mechanical separation techniques to separate the insulation from the metal cores. This method is less labour-intensive and requires less maintenance than wet separation. However, it may be less effective at separating very fine wires.

Both methods have their advantages and disadvantages, and the choice between wet and dry separation depends on various factors, including the type of cables to be processed, available resources, and the specific requirements of the recycling process. It is important to carefully consider these factors to find the most effective and sustainable solution for your specific needs.

What is a dismantling system?

The dismantling of used car catalytic converters is a crucial step in the recycling process. Here is a brief procedure description that takes into account the use of alligator shears and vertical shears:

Preparation:

The catalytic converter is first separated from other vehicle parts, either manually or with the help of machines.

Dismantling with alligator shears (CAT-SERIES):

Alligator shears are robust and powerful tools, ideal for cutting metal parts. They are often used to cut through the outer metal casing of the catalytic converter. However, due to their design, they may not always provide precise cuts.

Dismantling with vertical shears (VCAT-SERIES):

Vertical shears offer more precision than alligator shears. They are ideal for cutting the fine metal grid inside the catalytic converter. Due to their vertical alignment, they can perform accurate cuts, making the extraction of the valuable catalytic material more efficient.

Extraction of catalytic material:

After dismantling, the catalytic material, which contains valuable metals such as platinum, palladium, and rhodium, is extracted and collected for further processing and reuse.

It is important to note that both alligator shears and vertical shears have their own advantages and disadvantages. The choice of the right tool depends on various factors, such as the type of catalytic converter, available equipment, and the specific requirements of the recycling process. It is always advisable to follow safety regulations and wear appropriate protective gear to avoid injuries.

What products do you offer?

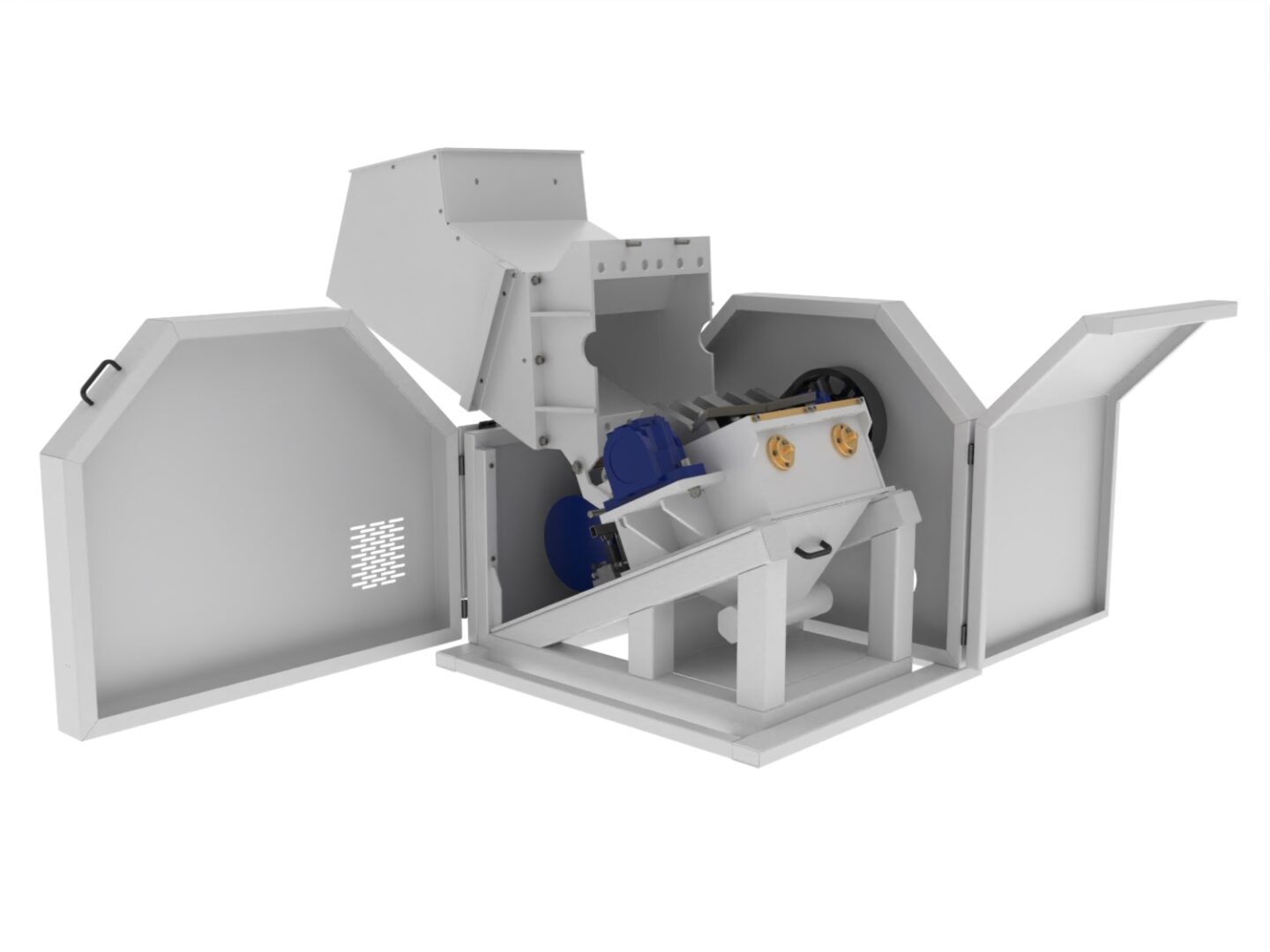

Shredding technology

- Cutting mills

- Shredders

- Hammer mills

- Grinding systems

Conveying technology

- Belt conveyors

- Screw conveyors

- Magnetic separators and magnetic drums

- Metering bunkers

Separation technology

- Dry separators

- Wet separators

Used and demonstration machines

- Cable recycling technology

- Dismantling technology

Additionally, we offer a comprehensive range of machines from renowned manufacturers that complement our product range:

- Alligator shears

- Cable stripping machines

- Baling presses

- Perforators

- Machines for processing underground cables

- Shredding technology for processing plastics

Can you offer customised solutions?

Yes, we can offer customised solutions for your specific requirements. Contact us to discuss your needs.

How can I get in touch?

You can reach us via the contact form on our website or by phone. We look forward to assisting you.

Any more questions?

Contact us for more information.