VCAT-SERIES

CATALYTIC CONVERTER RECYCLING VCAT

Dismantling system VCAT.12

The smallest model of the VCAT series.

The VCAT.12 vertical shear with a patented V-cut system is designed for processing all standard catalytic converters with ceramic cores. This entry-level model stands out with its robust and compact design, an integrated extraction system, and a processing capacity of 30-40 catalytic converters per hour. The catalytic converters are secured in the cutting area by the vertical blade, resulting in less deformation compared to processing with an alligator shear.

Technical Data

Installed power: 4.0 kW

Capacity: 30-40 pcs./h

Voltage level: 400 V | 50 Hz

Weight: project-dependent

Dimensions LxWxH: 1.060 x 1.065 x 1.810 mm

Dismantling system VCAT.20

The professional solution for dismantling catalytic converters with ceramic monoliths has been available in a new, updated design since 2022. The vertical shear with a patented V-cut system and integrated, high-performance extraction system stands out not only for its compactness but also for its processing capacity of 30-40 catalytic converters per hour. The filter cleaning of the extraction system is automatic, using compressed air. During the cutting process, the catalytic converter is secured by the vertical blade, resulting in less deformation compared to an alligator shear.

Technical Data

Installed power: 5,5 kW

Capacity: 30 – 40 Stck./h

Voltage level: 400 V | 50 Hz

Weight: project-dependent

Dimensions LxWxH: 1.075 x 1.075 x 2.285

Dismantling system VCAT.C

Ground-level complete system for dismantling used catalytic converters

The compact processing system VCAT.C is designed for the treatment of used catalytic converters with ceramic monoliths. In addition to the patented vertical cut and the re-opening device, it includes a grinding system that grinds the monolith fragments to a uniform particle size. The discharge from the grinding system is 100% loss-free, thanks to a vacuum conveyor system. As with the VCAT.C, work safety is ensured by a light curtain.

Technical Data

Capacity: 40 – 50 Stck./h

Voltage level: 400 V | 50 Hz

Weight: project-dependent

Dimensions LxWxH: 3.010 x 3.375 x 2.840

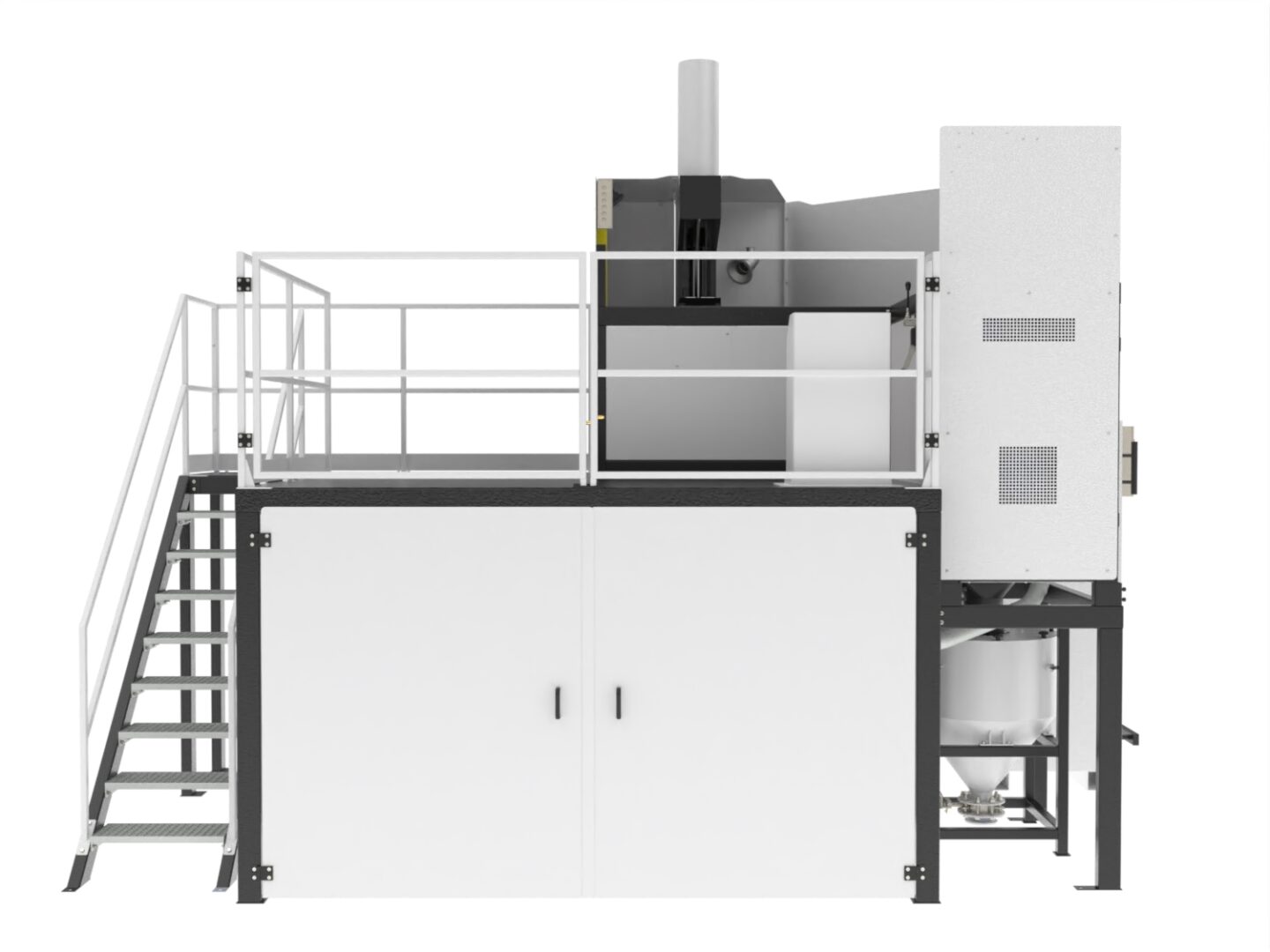

Dismantling system VCAT.P3-90

The platform variant of the complete VCAT.C system

The VCAT.P3-90 dismantling system provides everything needed for processing used catalytic converters with ceramic cores. The widened surface is sufficiently large to store two raw material cages and offers ample workspace. The lower part of the platform structure serves as an enclosed, sound-insulated area for storing emptied housings, which are disposed of through a drop chute. A light curtain secures the cutting area, ensuring protection against accidents during the work process.

Technical Data

Installed power: 19,8 kW

Capacity: 40 – 50 Stck./h

Voltage level: 400 V | 50 Hz

Weight: project-dependent

Dimensions LxWxH: 6.055 x 2.570 x 4.055

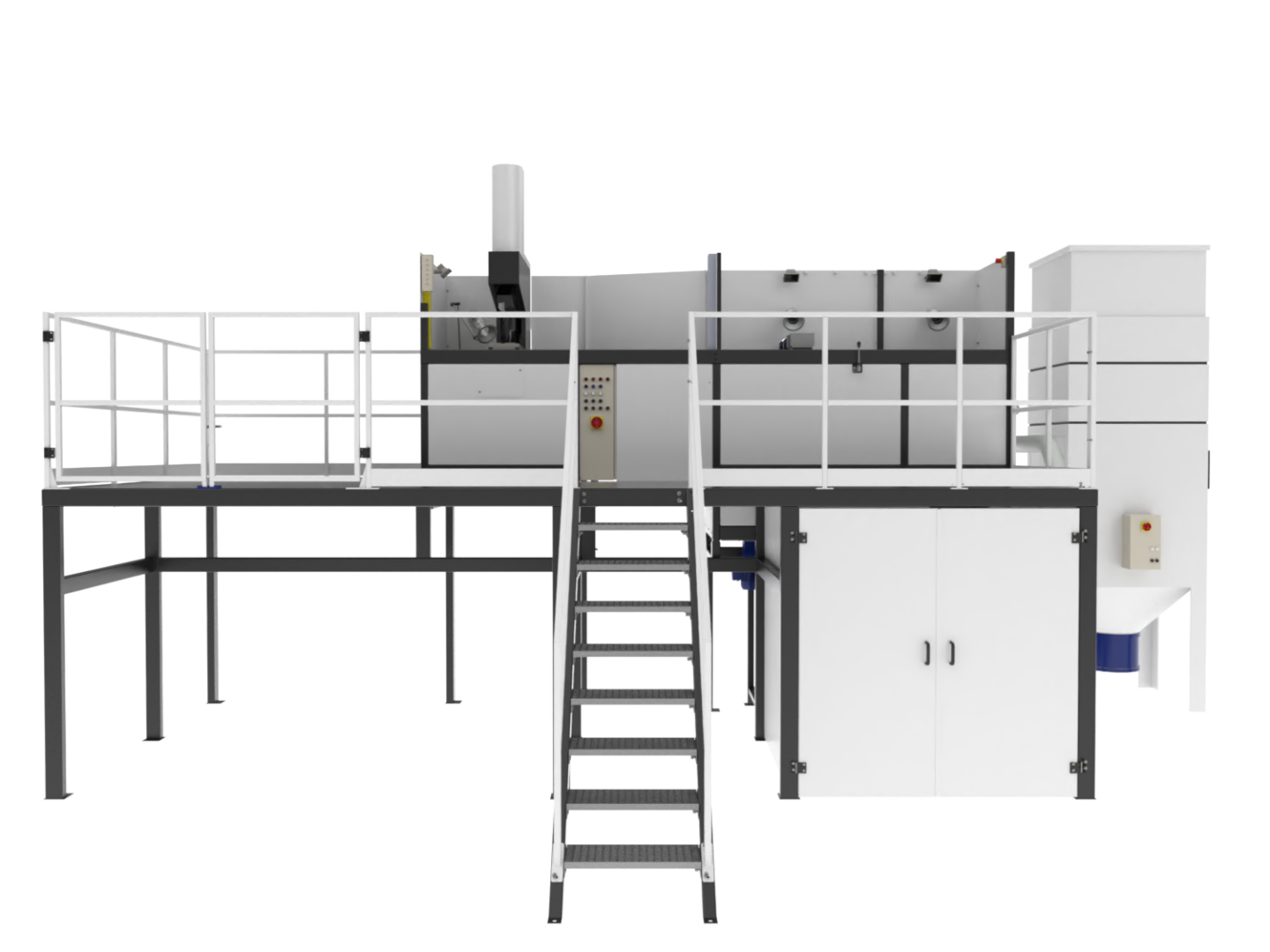

Dismantling system VCAT.P3-180

The VCAT.P3-180 dismantling system is ideal as a two-person workstation. Unlike the P3-90, the cutting and re-opening devices are arranged side by side, providing space for two operators. The cutting area is secured by a light curtain to ensure appropriate workplace safety. The lower part of the platform structure serves as an enclosed, sound-insulated area for the disposal of emptied catalytic converter housings. The platform also provides space for two raw material storage cages.

Technical Data

Installed power: 17,2 kW

Capacity: 40 – 50 Stck./h

Voltage level: 400 V | 50 Hz

Weight: project-dependent

Dimensions LxWxH: 7.705 x 4.880 x 4.055