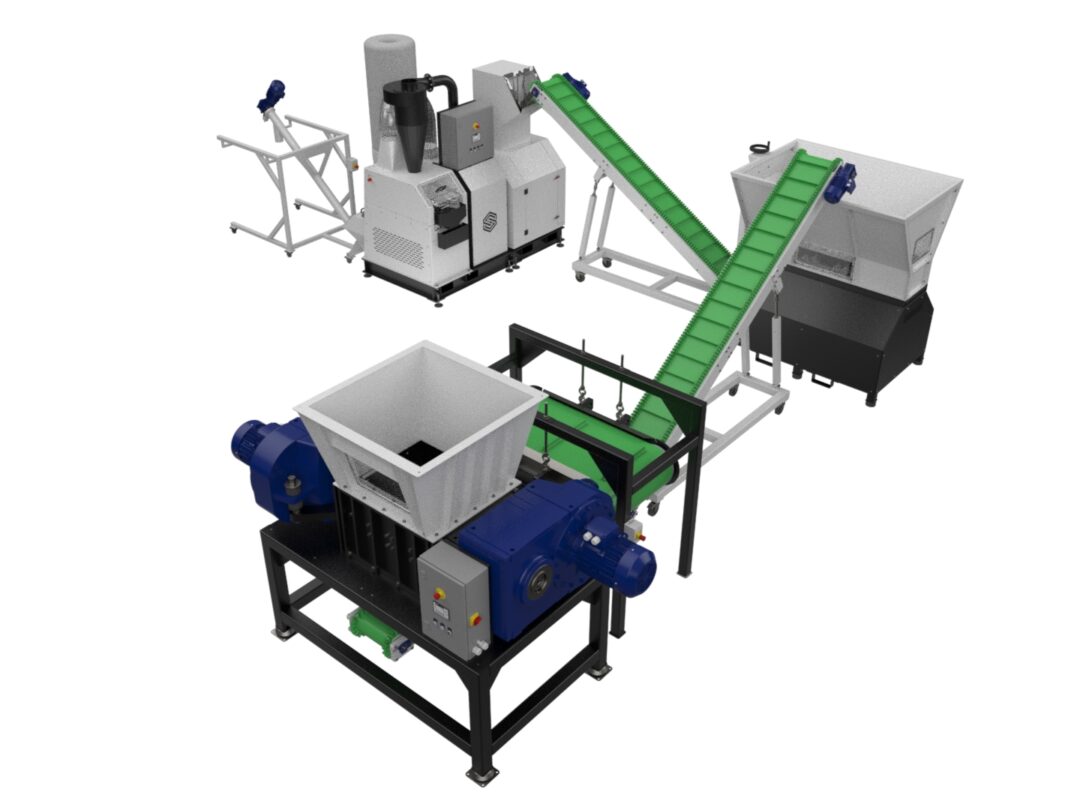

ICS Recycling Line

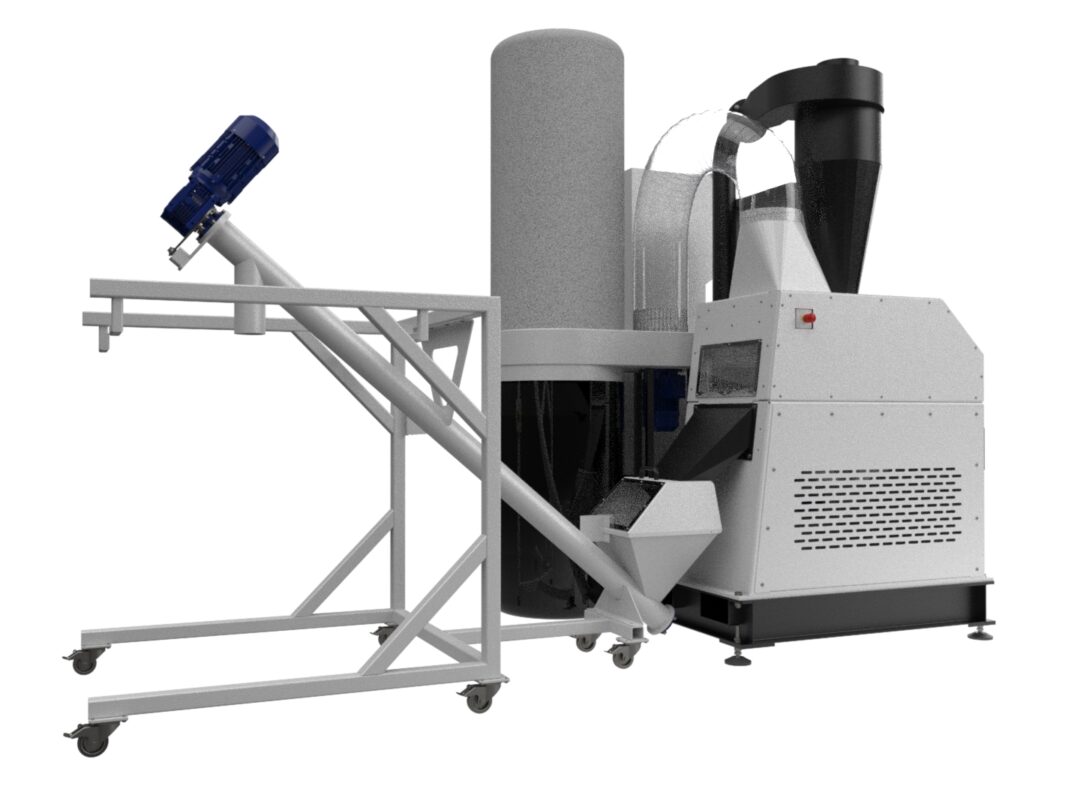

Cable Granulation Systems of the D-Series

The D-series granulation systems form the core of every recycling line. Here, copper and plastic are separated with a purity of up to 99.9%. This series offers processing capacities ranging from 110 kg/h to 800 kg/h and operates on the principle of dry separation.

First Expansion Stage: Screw Conveyor

In the first expansion stage, the plastic fraction is transported away via a screw conveyor. The lightweight fraction is directly discharged into a BIG-BAG, which is suspended from the frame of the screw conveyor.

Second Expansion Stage: Inclined Conveyor

The second expansion stage involves feeding material using an inclined conveyor. The conveyor is height-adjustable and can be adapted to various D-series systems. Material input is easily handled via a feed hopper.

Dosing Bunker ZBB

The ZBB dosing bunker allows for material storage and controlled discharge. Unlike comparable solutions, this system keeps the entire bunker content in motion, preventing bridging within the interior.

Feeding the Dosing Bunker

Like the second expansion stage, the dosing bunker is fed using an inclined conveyor with an appropriate feed hopper.

Conveyor Belt with Overband Magnet

An important and recommended addition is a horizontal conveyor belt with an overband magnet. This solution is placed between the pre-shredder and the cable granulation system to prevent contamination of the material.