Vertical Shear or Alligator Shear?

What to Consider in Catalytic Converter Recycling!

Introduction:

Efficient dismantling methods are crucial for recovering valuable materials during catalytic converter recycling. Two common methods employed in this process are alligator shears and vertical shears. Both offer specific advantages and disadvantages that must be considered. In this article, we will take a closer look at these two methods, examining their differences, pros, and cons.

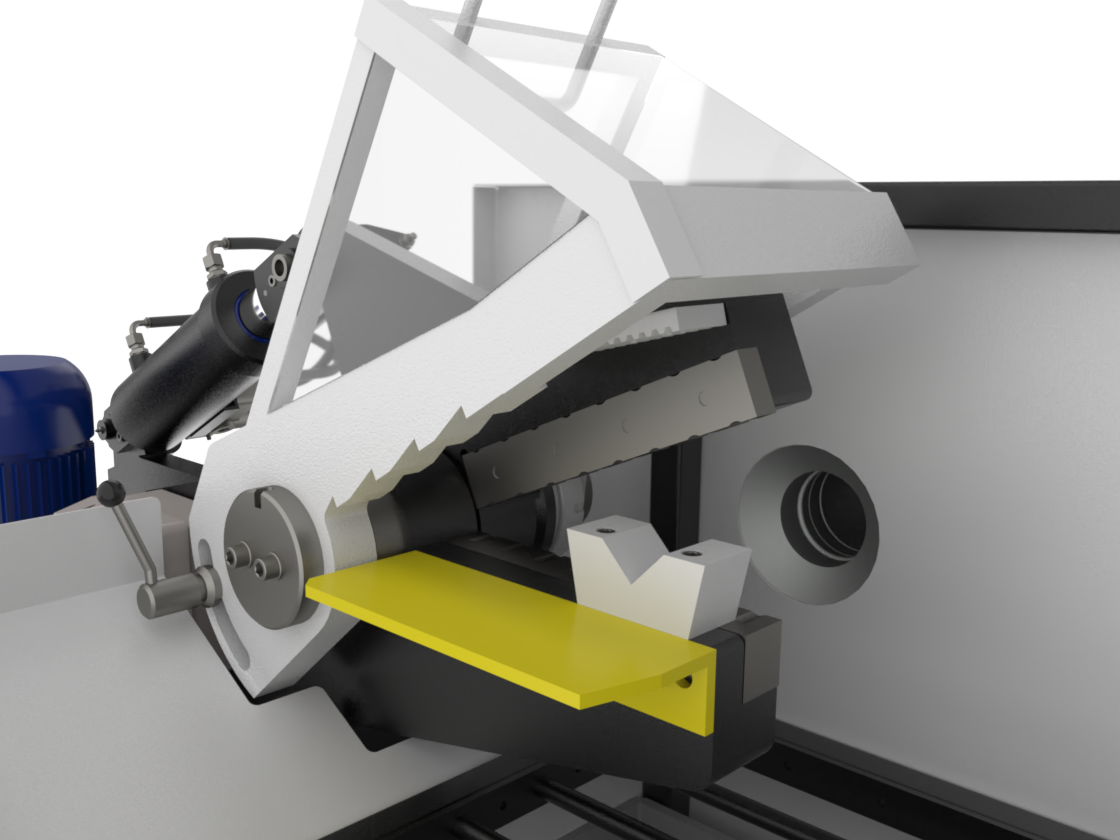

Alligator Shears:

Alligator shears are widely used for dismantling catalytic converters and other scrap materials. They feature a hydraulic cutting system that applies significant cutting force to sever the catalytic converters. The cutting arms move horizontally, pressing the material between them to cut it.

Advantages:

- Versatility: Alligator shears are not only suitable for catalytic converters but can also be used for dismantling other types of scrap.

- High cutting force: Thanks to the hydraulic system, alligator shears can easily cut through thicker materials.

- Durability: They are typically robustly built and suited for demanding environments.

Disadvantages:

- Health and safety risks: The horizontal movement of the cutting arms can pose risks to health and safety, especially if unexpected material movement occurs.

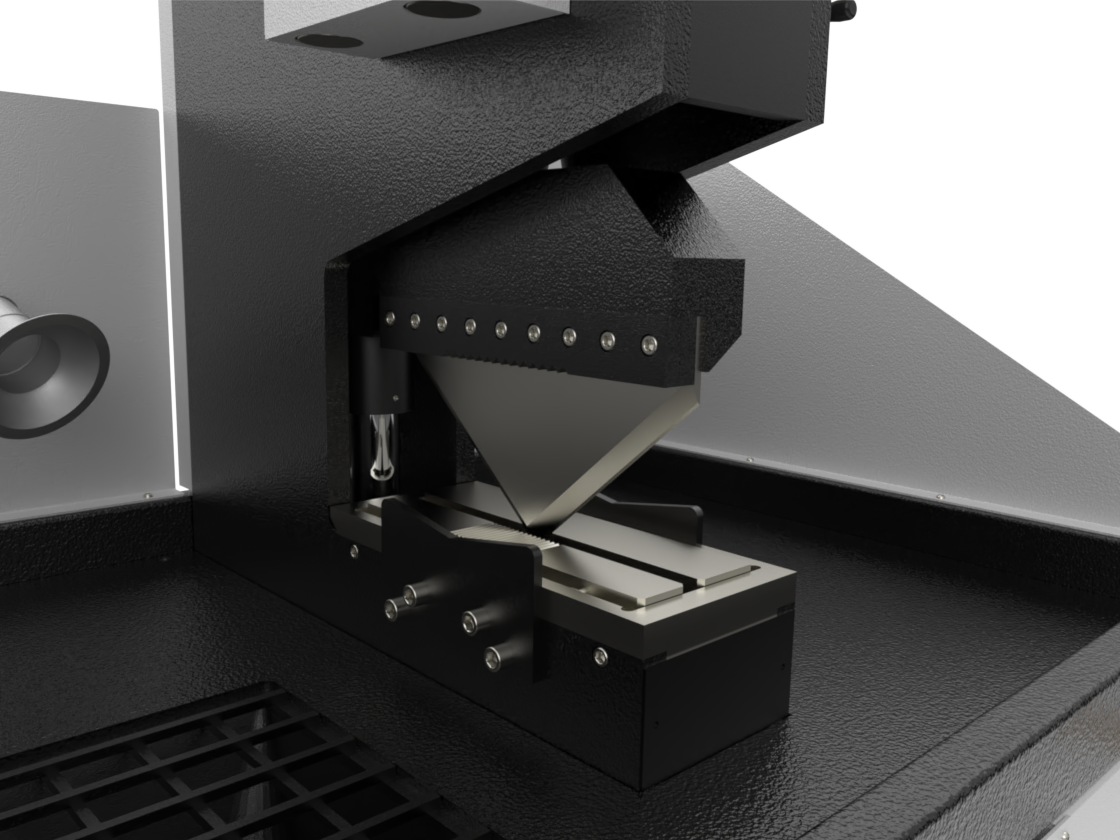

Vertical Shears:

Vertical shears are an alternative method for dismantling catalytic converters, characterised by their vertical cutting motion. They consist of a vertical cutting system that cuts the material from top to bottom.

Advantages:

- Reduced material loss: The vertical cutting motion of vertical shears helps reduce the loss of valuable materials.

- Better material positioning: The top-down cutting allows for more precise positioning, resulting in less deformation.

- Increased safety: The vertical movement reduces the risk of unexpected material shifts, creating a safer work environment.

Disadvantages:

- Potential limitations in processing other scrap types: While vertical shears are effective for catalytic converters, they may not be as versatile as alligator shears for other scrap materials.

Conclusion:

The choice between alligator shears and vertical shears for dismantling catalytic converters depends on several factors, including the desired precision, material loss, and versatility of the machine. While alligator shears offer versatility and high cutting force, vertical shears stand out for their reduced material loss and increased safety. Ultimately, the decision should be based on which method best suits the specific requirements of the recycling process.